iQSim

iQSIm, the the Leonardo da Vinci Development of Inovation project, Innovative Simulator Tools for Quality management Production Process Training in Vocational Education and Training (2008 – 2010) developed "What happends if….. simulator services" for mechanical industry in Europe. The tools and services are still used by vocational education and training providers and mechanical industry in many countries in Europe, for instance in Romania, Serbia, Hungary, Sweden and Norway.

- The iQSim tools may be accessed from here. Please notice that you will have to click on the "Get flash link" if the page is blank.

- The English version of the iQSim user manual is available here.

The tools and sevices are currently maintained by the Norwegian University of Science and Technology - NTNU in Trondheim, Norway. Questions, feedback and request for support may be sent to john.b.stav@ntnu.no

How does iQSim work?

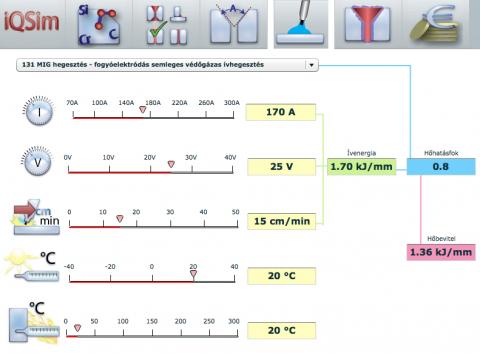

The services use Flash and Flex, are prepared for presentations on digital blackboards, and all mathematical calculations are embedded into the software. The services have the advantage that students and instructors may use learning activities where they use sliders to “play” dynamically with the essential welding parameters in order to observe the tolerance window occurring in real-life production facilities. It’s possible to investigate the influence of a number of variables in order to figure out which variables have the biggest impact on the quality of the final products. From an instructional point of view, the evaluator helps to reduce manufacturing defects by making up alternative decision routes that include both technical and economical production tasks.

Key feaures are:

- iQSim performs real-time online calculations of welding processes.

- Flexibillity: The Flash-based interface is easy to use and can be used to simulate «what if» scenarios which are hard to do in a lab.

- Integrable: iQSim works seamlessly with digital whiteboards by using a Flash and Flex based point-and-click interface and sliders to adjust parameters.

- Adaptable: iQSim can be adapted to any number of teaching methodologies, including Activity Based Training.

iQSim aimed to develope and disseminate a new generation of training methodologies that are applicable to European wide mechanical industry sectors, including fabrication industries, vocational education and training (VET) schools and SME’s.

Results:

The 6 basic components of the iQSim services are:

- Defining material constants

- Selecting geometries

- Fine tuning the geometry

- Select welding method

- Display temperature in HAZ

- Perform cost and economical calculations

Evaluation tools include the most frequently used welding methods:

- MMA

- TIG

- FCAW

- MIG/MAG

Tools for evaluation of the most frequently used joint configurations or bevels:

- Square butt (I-bevel)

- V-bevel

- Fillet weld

- X-bevel

Calculation of production costs for the four welding methods and bevel configurations above.

Online evaluation services provide quality assurance design by including risk analysis into the training environment.

iQSim offers accesss to new pedagogical methodologies that help improving the quality assurance process of industrial production process training.

Impact:

Welding institutes, vocational education and training schools and mechanical industry companies may utilize the online evaluator learning environment in combination with the new pedagogical methods, to offer a broad range of specalized courses at a European level.

The teacher and students may play with the variables dynamically, using sliders in order to create ”what happens if” scenarios, such as:

- What influence will the root gap has on the economy?

- Does tolerance in the bevel angle influence the welding costs?

- Which welding methods give the widest set of production tolerances ?

- Which of the welding parameters have the greatest influence on the heat input ?

- Which welding parameter is the most important one when the HAZ value are going be maintained ?

A picture of the simulator.

Summary of main features:

- The on-line simulator services help displaying critical production parameters in the mechanical industry sector

- Simulator tools and services include the 4 most frequently used welding joints, and the calculation of production costs for these welding methods

- Validation of the new simulator tools has been done in vocational education and training in Norway, Sweden, Hungary, Lithuania, Romania and Serbia

- Offers new pedagogical methods which may combine and utilize face-to-face training, e-learning solutions, simulations and high quality video

- Dedicated services for digital blackboards by using object oriented programming

- The graphical user interface hides all advanced calculations

DISCLAIMER:

The European Commission's support for the production of this publication does not constitute an endorsement of the contents, which reflect the views only of the authors, and the Commission cannot be held responsible for any use which may be made of the information contained therein.